Duct Seal HG Cable Duct Sealing System (large heavy cables) - ≤2 Bar Pressure Resistance

Description

Duct Seal HG (Water & Gas) Duct Sealing System for Large Cables and Pipes - ≤2 Bar Pressure Resistance

The Duct Seal HG system is a re-enterable duct sealing solution specifically designed for large, heavy cables and pipes in complex duct scenarios. It effectively prevents the ingress of harmful or flammable gases, liquids, smoke, and vermin, keeping installations safe and secure. Whether used in data centres, substations, or waste-to-energy plants, Duct Seal HG has got you covered.

Duct Seal HG Features

-

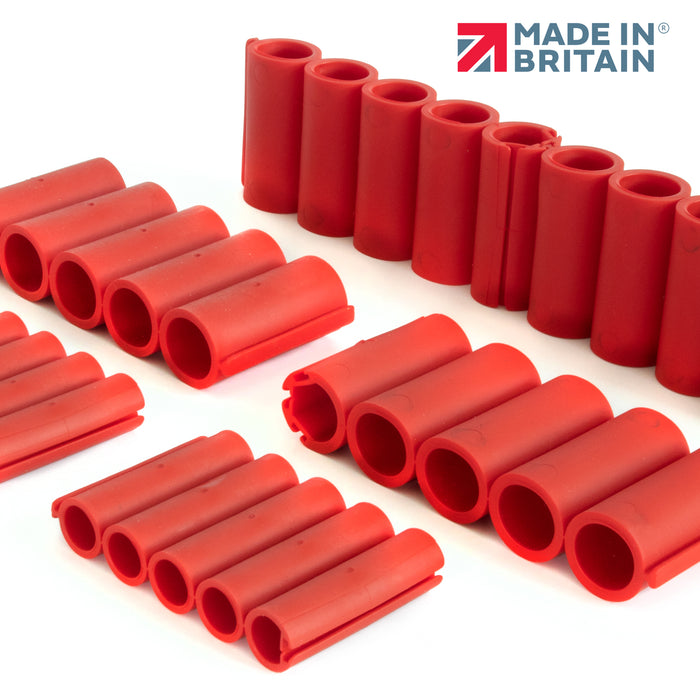

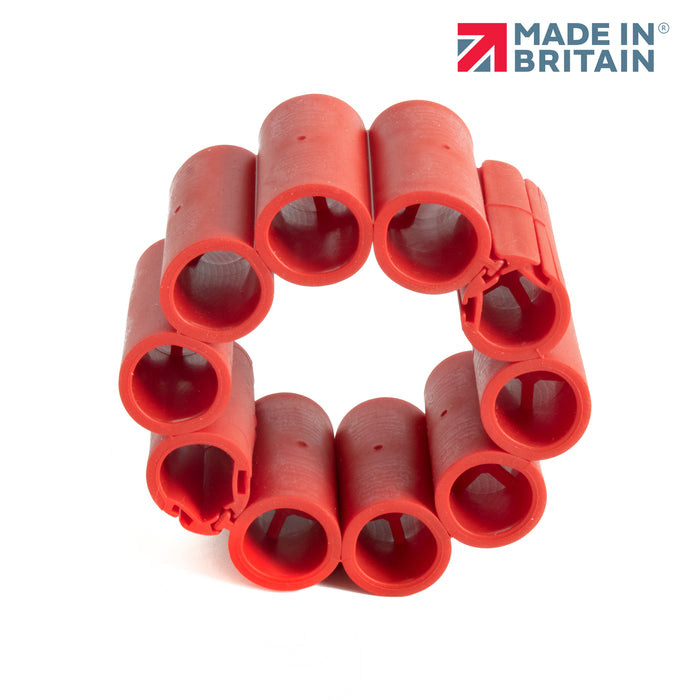

Patent Pending Trefoil/Triplex Cable Separation: Our tubular rubber backing system can be configured in continuous strips, rings, or cross shapes, providing optimal support and separation for large cables or pipes. This unique design, suitable for trefoil cables and raceway seals, simplifies installation and meets DSEAR compliance.

-

MEKO-Free, Fybrid, Non-Hazardous Intumescent Sealant: Duct Seal HG uses our advanced Grey Stuff and Red Stuff sealants. These flexible, zero-halogen, MEKO-free sealants ensure safety for installers and the environment alike.

-

Water & Gas Tight: The Duct Seal HG system provides a solid barrier against water and gas, making it perfect for critical infrastructure applications.

-

Toxic Gases Resistant: Specifically designed for the water industry, Duct Seal HG resists gases like methane, chlorine, and hydrogen sulphide.

-

Hydrocarbons Resistant: Designed for petrol forecourt applications, Duct Seal HG withstands exposure to hydrocarbons, making it ideal for installations in areas with chemical agents.

-

Flame Retardant: Duct Seal HG has been tested to UL94:2013 ANSI / UL 94:2018 standards for flame retardancy.

-

Industry Compliant: Duct Seal HG meets standards including DSEAR, WIMES, DCG, APEA, the Blue Book, and ATEX, ensuring suitability for a range of demanding sectors.

-

Microbial Defence: Built-in resistance against fungi and bacteria ensures long-lasting protection in tough environments.

-

Prevents Water Treeing: Duct Seal HG forms a watertight seal, blocking moisture and safeguarding cables from water treeing damage.

-

Low Cable De-Rating: With a 20mm thickness, the thermal resistance is only 5.1 K/W, ensuring the cable maintains its maximum current capacity.

-

MADE IN UK: All Duct Seal HG components are proudly designed and manufactured in the UK, ensuring quality and craftsmanship.

Duct Seal HG Applications

Data Centres: Provides a reliable seal around large cables in critical data infrastructure, protecting against external environmental threats.

Substations: Effectively seals ducts in electrical substations, blocking harmful substances from entering.

Pumping Stations: A solution for the water industry where toxic gas resistance and a secure, water-tight seal are essential.

Waste-to-Energy Plants: Built for harsh environmental conditions, ensuring long-term duct integrity in waste-to-energy facilities.

Wind Farms/Turbines: Offers robust protection for renewable energy installations that operate in exposed environments.

Electrical Utilities: Ensures safe and secure duct sealing for various electrical utility applications.

Rail Industry: Meets Network Rail standards, making it ideal for rail infrastructure projects.

Why Choose Duct Seal HG for Duct Sealing?

Duct Seal HG isn’t just another duct sealing system—it’s a patented solution that meets the highest industry standards. With features like trefoil/triplex cable separation and advanced intumescent sealants, Duct Seal HG offers:

-

Unbeatable Flexibility and Protection: The re-enterable design allows easy maintenance and adjustments. Its unique backing system supports large cables, making it suitable for complex cable scenarios.

-

Compliance and Safety: Meeting DSEAR, WIMES, and other industry standards, Duct Seal HG ensures installations are safe and compliant with regulations.

-

Environmentally Safe and Non-Hazardous: FyBrid technology ensures the Grey Stuff and Red Stuff sealants are non-hazardous and environmentally friendly, providing peace of mind for installers and end-users.

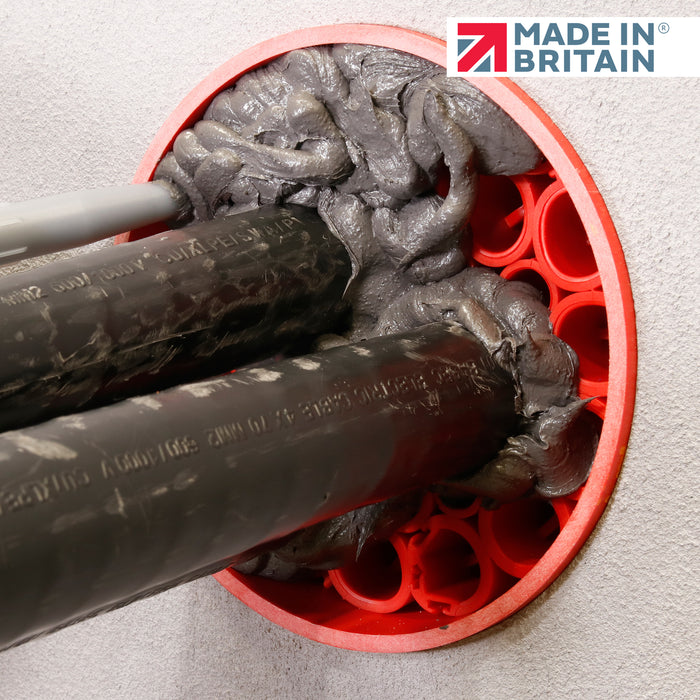

Installations

-

Abrade the First 20mm: Lightly abrade the initial 20mm of the duct and cables to remove grease, old sealant, and dust, creating a clean surface for the sealing compound.

-

Clean the Duct and Cables: Remove all debris, grease, and dirt to ensure the Grey Stuff or Red Stuff sealant bonds well.

-

Insert Larger Tubes/Sleeves: Begin with the larger tubes or sleeves, inserting them into the duct to separate the cables from the inner duct wall. For trefoil cables, join the larger tubes to create a cross shape to maintain separation among the cables.

-

Fill Smaller Gaps: Use additional tubes to fill any remaining gaps, forming a solid support structure.

-

Adjust Tube Depth: If the tubes are too deep, use long-nose pliers to position them approximately 20mm from the duct edge.

-

Apply the Grey Stuff or Red Stuff Sealant: Begin at the bottom and work upwards for complete coverage.

-

Finish with the Magic Sponge: Wet and squeeze the Magic Sponge, then dab it over the sealant to ensure it adheres to both the cables and duct, leaving a clean finish.

-

Complete: Your installation is now secure and sealed.

FAQs

What’s the difference between Duct Seal HG and other duct sealing kits?

Duct Seal HG includes patented trefoil/triplex cable separation and advanced FyBrid intumescent sealants. This unique combination provides exceptional flexibility, protection, and compliance with industry standards, making it one of the best duct sealing solutions available.

Is Duct Seal HG suitable for harsh environments?

Yes, Duct Seal HG is designed to endure harsh conditions, making it ideal for applications in the water industry, petrol forecourts, and other demanding sectors.

Can Duct Seal HG be used for retrofits?

Absolutely. The Duct Seal HG system is re-enterable and can be installed retrospectively, providing flexible, long-term protection for both new installations and retrofits.

Is Duct Seal HG WIMES compliant?

Yes, Duct Seal HG complies with WIMES standards and is used by water authorities across the UK and Ireland. Compliance includes WIMES number 3.02 2019 clause 6.4.3.2D(b).

Why AC Cable Solutions?

AC Cable Solutions supplies high-quality, British-made duct sealing solutions. Our products are built for performance, backed by a dedicated customer support team.

Features & Standards

| Feature | Measurement | Notes / Standards |

|---|---|---|

| Water & Gas Tight | 2.0 bar | Pressure tested & certified |

| Non-slumping | – | Maintains form during application |

| Density | 1.27 | Stable & uniform |

| Colour | Anthracite Grey / Brick Red | Easy identification |

| Odourless when curing | – | User safe |

| Skin Over Time | 10 mins | At 23°C / 50% RH |

| Flexible | 3–4mm cure/day | Humidity & temp dependent |

| Tack Free Time | 22 mins | Fast handling time |

| Hardness | 35–38 Shore A | Rubber-like finish |

| Elongation | 250% | High flexibility |

| UV & Ozone Resistant | – | Outdoor durability |

| Flow | 3.33M cPs @ 380°C | Thermal stability |

| Tensile Strength | 0.72 N/mm² | Strong adhesion |

| Operating Temp | +5°C to +40°C | Application range |

| Temp Resistance | -35°C to +120°C | After cure |

| Intumescent | Activates @ 210°C | Expands under fire |

| Hydrocarbon Resistant | – | Petrol, Diesel, ASTM oil, LPG |

| Gas Resistant | – | Methane, H₂S, Chlorine |

| Other Resistance | – | ADBLUE, Antifreeze |

| Microbial Defence | – | Fungi, E-Coli, S. aureus, A. brasiliensis |

| Halogen Free | Yes | Zero halogens |

| MEKO Emission | 0% | Safe & compliant |

| Shelf Life | 12 months | Store cool, dry |

| Compliance | – | DSEAR, WIMES 3.02:2019, NEC, APEA Blue Book 4.6.8, ATEX |

| Age Tested | 50 years | Independently verified |